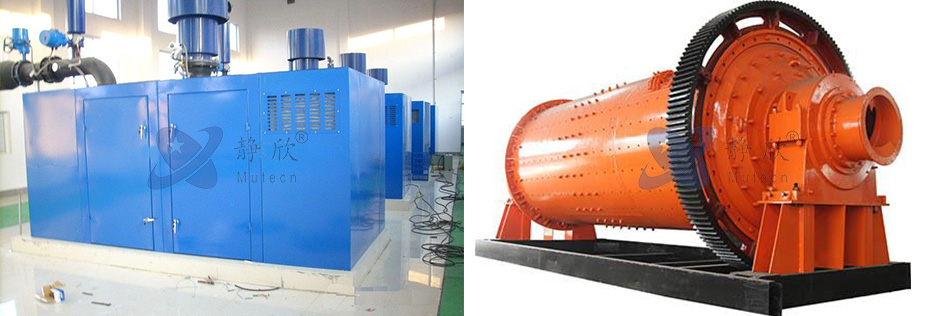

Noise reduction project of ball mill

Publish date:2018-06-27 Views:698

Engineering Introduction:

The noise of ball mill is mainly composed of noise of cylinder, motor, reducer and gear. The noise of ball mill is 75db (A). This is a noise generated by the impact and vibration of steel balls, liner and colliding, impact and friction. Theoretical research and practical measurement show that the sound level of cylinder noise is higher than that of auxiliary machine noise 10dB. The key to control the noise of ball mill is to reduce the noise of cylinder. Only by comprehensive control of ball mills and auxiliaries can we ensure the realization of soundproof targets.

Solution:

1, use the sound insulation cover: it can be divided into three forms: fixed, movable and curtain. Generally, the fixed sound insulation cover has a high sound insulation capacity, which can reach 25 - 30dB (A), but the ventilation performance is poor and the maintenance and maintenance is difficult. The active sound insulation cover is improved on the basis of the fixed sound insulation cover, and the maintenance performance is improved, but the sound insulation can be reduced to 20 to 25dB (A), ventilation and heat dissipation problems It still exists, at the same time, it needs to occupy a large space and space; curtain type sound insulation cover is developed to solve the contradiction between the occupying space and the space of the active sound insulation cover. It has the advantages of dismantled storage. The problem is still the difference of ventilation and heat dissipation, and the price is high. All of the above three kinds of sound insulation covers are controlled by the way of noise transmission, and they are large and passive. Under conditions and environment conditions, it is an effective means of expedience.

2. Replacing manganese steel liner with rubber liner is one of the technical measures based on the mechanism of the ball mill noise. The effect of noise reduction is obvious. But at present, the high temperature resistance and wear resistance of synthetic rubber are poor, the service life is short and the cost is expensive, because this is before the improvement of the material performance, It is difficult to popularize the application.

3. The sound insulation of the ball mill cylinder is another basic measure to reduce the sound of the barrel. This method overcomes the difficulty of the ventilation and heat dissipation of the sound insulation cover and the difficulty of maintaining the synthetic rubber liner on the material performance. It is an economical and practical technical measure. The key technology lies in reasonable structural design and appropriate damping material selection. The noise reduction effect can reach 8 - 10dB (A).