MUTE Introduction and installation of floating rubber vibration isolation sound insulation pad

Publish date:2018-07-13 Views:790

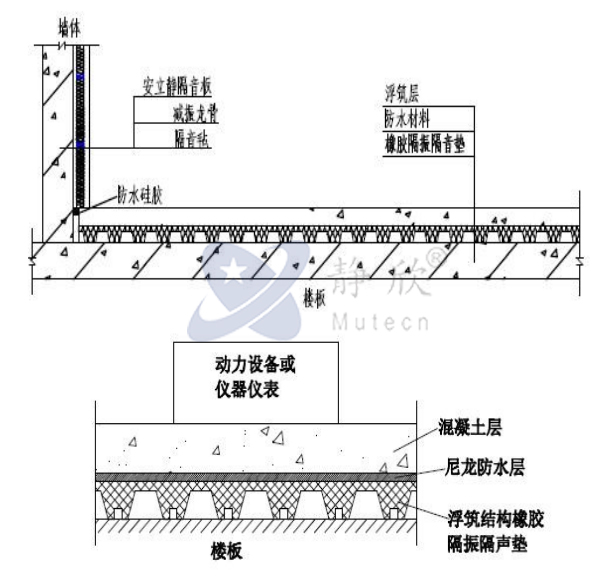

One, floated structure of floor slab:

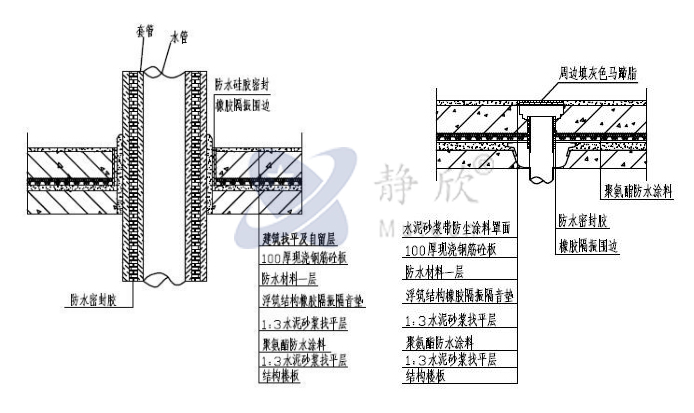

Two. Vibration and waterproofing measures for pipelines and floor drain crossing floating structures:

Three. Product sample:

The MUTE type floating rubber vibration isolation pad is mainly composed of natural synthetic rubber, the middle polyamide nylon skeleton reinforced layer is formed by high temperature vulcanization and molding, and the lower convex platform has a hole. It can play a certain air isolation and damping effect, the natural frequency is low, the vibration isolation effect is good, and the main purpose is to be used in the isolation and isolation of the floating and power equipment. The noise can be reduced to the maximum extent, and the vibration of buildings and the transmission pollution of noise can be isolated.

The size of the product is 500*500mm, which can be laid in a large area. It can also cut the size according to the needs of the project.

It can be resistant to acid, alkali, oil, anticorrosion, mildew proof, moisture proof and anti-aging. The temperature range is -20-90 C, the damping ratio is 0.08.

|

型号 |

荷载 Kg/m² |

变形量 mm |

频率 Hz |

隔声量 dBA |

产品厚度 mm |

|

MUTE-50 |

200-1500 |

3-10 |

7.5-13 |

28-35 |

50 |

Four, floating building structure vibration isolation installation installation Description:

1. laying the ground need leveling, sharp protuberance and stones and other debris need to be cleaned.

2. the joints of the parallel laying vibration isolation gasket should be closely closed, and the joints should be pasted with 60mm tape.

3. after laying, the thick 0.2mm waterproof nylon film is completely covered on the isolating and sound insulation pad, and the surrounding edge of the film must be higher than 100-150mm, which is installed on the side of the vibration isolation pad, so as to prevent the infiltration of liquid.

4. lateral isolation (column) installation of vibration isolation gasket, thickness of more than 10mm, height of the product depends on the height of the floating platform, and can also be used for cutting products.

5. After pouring all the floating platforms, it is better to use waterproof silica gel on the side mounting pad.

6. The point lay type installation is first laid on the floor or foundation by the design drawing on the installation position. Then the "pad" is arranged according to the size. The bottom is fixed with adhesive and floor, the upper layer is laid with multilayer wood board and waterproof film nylon layer. It must be able to bear the load when pouring reinforced concrete.

7. if the construction is not a one-time pouring concrete, should consider adding the structure to connect the reinforcing bar in the connection position, after pouring concrete, it is necessary to pay attention to the spatter part of the timely cleaning.

8. until the concrete reaches the maintenance period (usually about 10 days or according to the actual situation), heavy equipment can be placed on the floating platform.

9. the equipment or other building components on the floating platform can not be directly contacted with other surrounding buildings, so as to prevent vibration transmission.

Five. Installation examples: